Ship Testing Services

Ballast water if not managed efficiently can cause the migration of harmful flora and fauna at the discharge location; the non-indigenous, environmental unfriendly and pathogenic organisms may continue to live and make a permanent basis at the discharged place. Here comes the requirement for ballast water treatment and testing of the treated water to verify the onboard treatment efficiency.

Ballast Water D2-Standard Testing

The International Convention for the Control and Management of Ships' Ballast Water and Sediments (BWM Convention) was adopted in 2004 to introduce global regulations to control the transfer of potentially invasive species. With the treaty now in force, ships need to manage their ballast water. The BWM Convention entered into force on 8 September 2017.

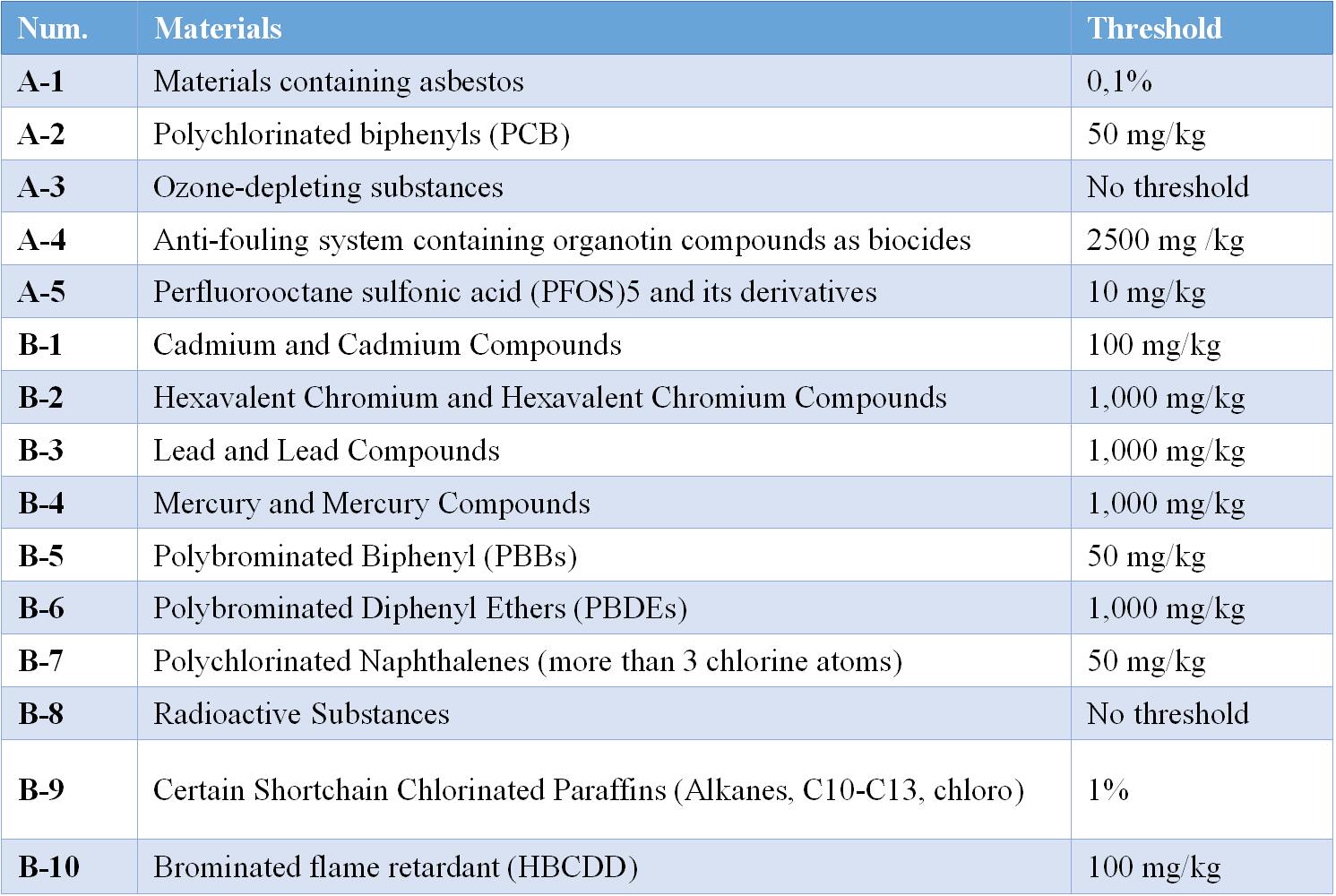

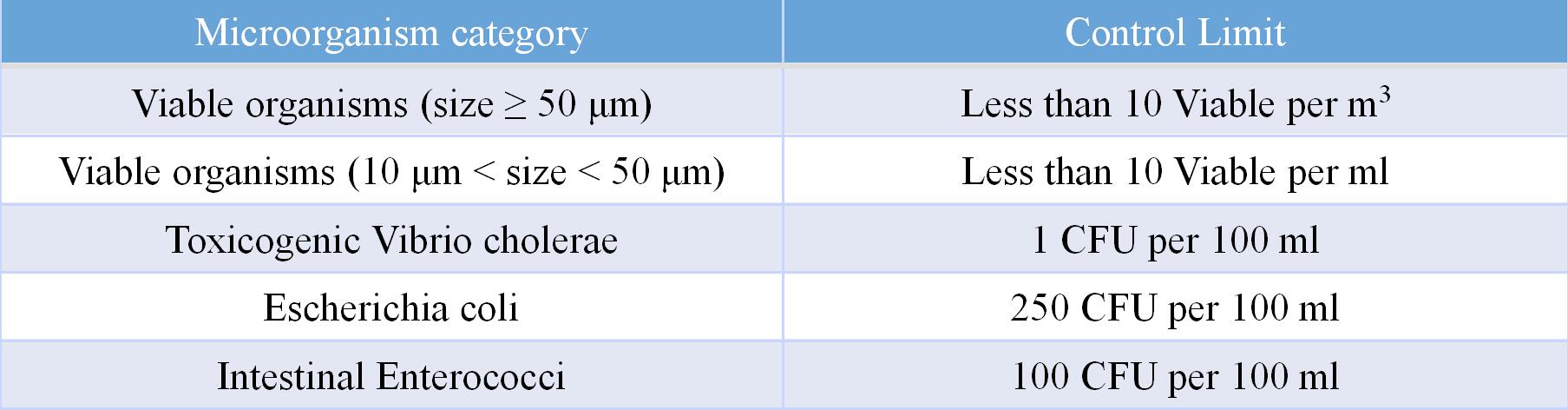

Every vessel that has installed a Ballast Water Treatment System must comply with the following discharge limits of the D2-Standard.

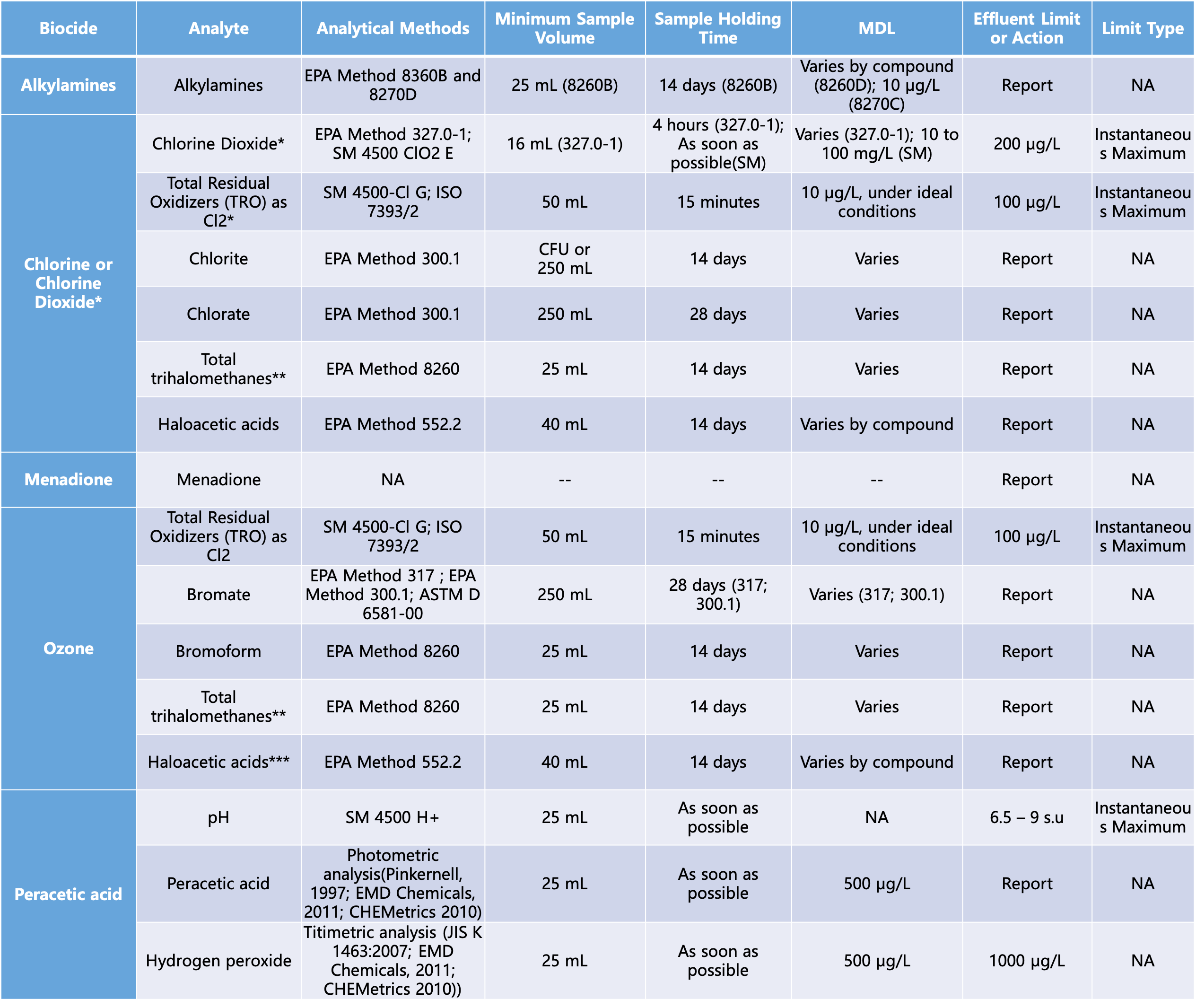

Ballast Water - VGP Compliance Monitoring

VGP’s ballast water monitoring requirements apply to ballast water discharges from vessels employing ballast water treatment systems that are used to achieve the effluent limitations.

Biological indicator compliance monitoring sampling of ballast water effluent must be conducted 2 times during the first year the system is installed or used for vessels with Devices for Which High Quality Type Approval Data Are Available are available.

For vessels with high quality data, if sampling results are below permit limits for two consecutive events, the vessel owner/operator may reduce monitoring to one time per year after the first year.

However, if the vessel owner/operator exceeds a permit limit on any sampling event, they must return to monitoring two times per year until they have two additional results below permit limits.

For vessels for which high quality data are not available, monitoring must be conducted 4 times per year.

For all vessels, one of those samples may be conducted as part a vessel’s annual or other survey, and during the first year, one of those sampling events may be conducted as part of the installation of the system to ensure it is functioning properly.

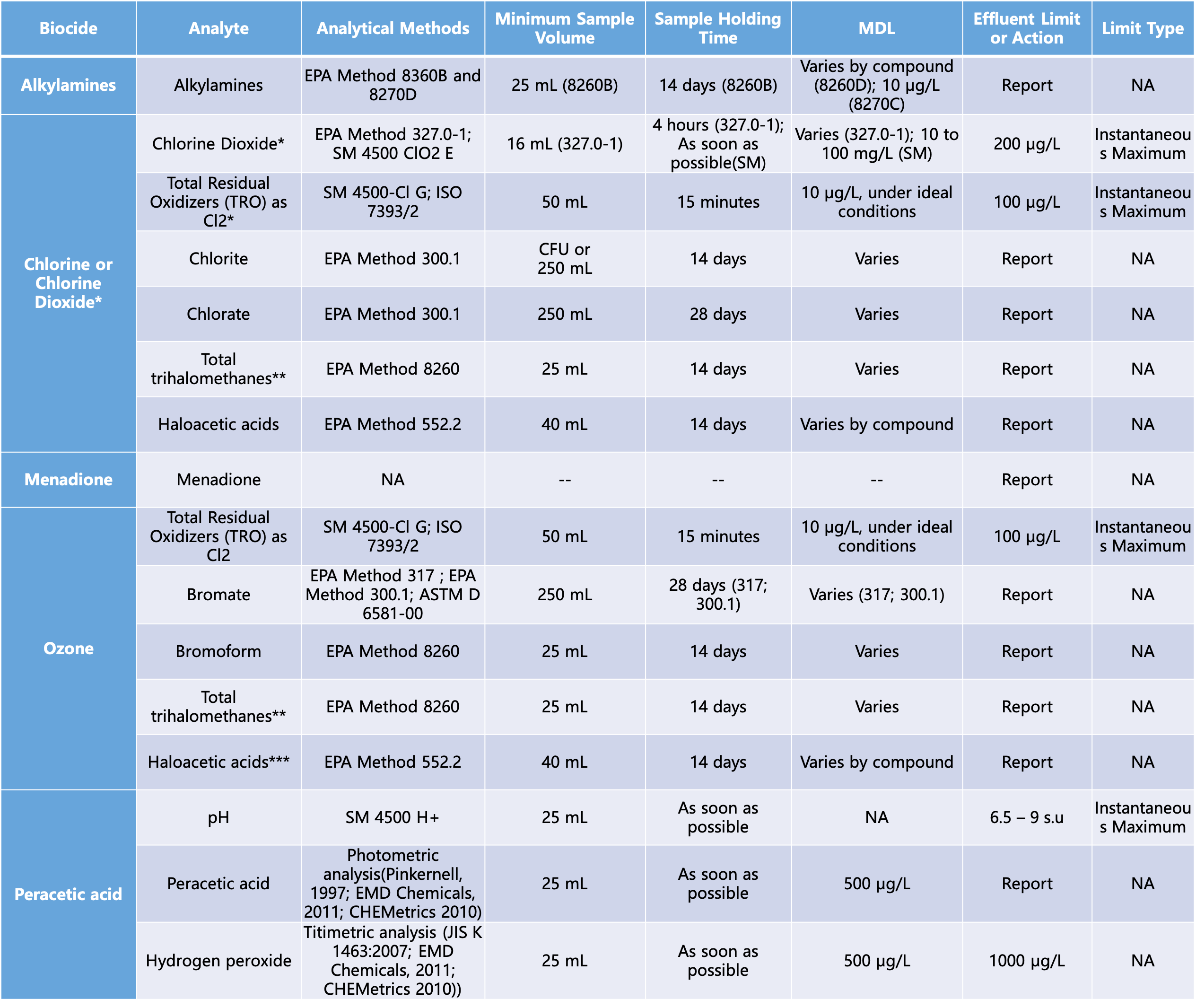

At the same time, if necessary, it is also necessary to monitor the biocides and residuals generated by the equipment.

We offer

Onboard Attendance for Sampling acc. to ETV Protocol, as well as BWMS code and Field Testing acc. To 40 CFR 136.3 methods.

Sampling bottles and containers as per VGP methods’ requirements.

Transportation of the samples within the required timeframes.

Transportation of the samples with the required conditions (preservatives/light/temperature conditions etc)

Lab Testing with EPA designated methods (40 CFR 136.3 methods) in Accredited Laboratories

Reporting as per EPA requirements

Guidance on Regulations Technical Support and Customer Care.

IMO Scrubber Washwater Testing

MEPC.259(68)

The wash water discharge criteria are intended to act as initial guidance for implementing EGC system designs. The criteria should be revised in the future as more data becomes available on the contents of the discharge and its effects, taking into account any advice given by GESAMP.

Administrations should therefore provide for collection of relevant data. To this end, shipowners in conjunction with the EGC manufacturer are requested to sample and analyse samples of:

inlet water (for background);

water after the scrubber (but before any treatment system); and

water after the scrubber (but before any treatment system); and

discharge water.

This sampling could be made during approval testing or shortly after commissioning and at about twelve-month intervals for a period of two years of operation (minimum of three samples). Sampling guidance and analysis should be undertaken by laboratories using EPA or ISO test procedures for the following parameters:

pH

PAH and oil (detailed GC-MS analysis)

Nitrate

Nitrite

Cd ,Cu,Ni ,Pb ,Zn ,As ,Cr ,V

The extent of laboratory testing may be varied or enhanced in the light of developing knowledge.

When submitting sample data to the Administration, information should also be included on wash water discharge flow rates, dilution of discharge, if applicable, and engine power should be included as well as specifications of the fuel used from the bunker delivery note as a minimum.

It is recommended that the ship that has provided this information to the satisfaction of the Administration should be granted a waiver for compliance of the existing installation(s) to possible future stricter wash water discharge standards. The Administration should forward information submitted on this issue to the Organization for dissemination by the appropriate mechanisms.

Our service offers:

Sampling Kits with the appropriate preservatives

Transportation of the kits to the vessel

Equipment for Onboard Testing (pH)

Step by Step Sampling Instructions

Sample Transportation Arrangements

Reporting as per IMO requirements

VGP Scrubber Washwater Testing

A per VGP, Vessel owner/operators must collect and analyze two samples in the first year of permit coverage or system operation, whichever is first, for each of the constituents analyzed in Part 2.2.26.2.3 to demonstrate treatment equipment maintenance, probe accuracy, and compliance with this permit.

Samples must not be collected within 14 days of each other.

Samples must be collected for inlet water (for background), water after the scrubber (but before any treatment system), and discharge water. For all vessels, one of those samples may be conducted as part a vessel’s annual or other survey, and during the first year, one of those sampling events may be conducted as part of the installation of the system to ensure it is functioning properly.

After the first year, samples must be collected at least once per calendar year for inlet water (for background), water after the scrubber (but before any treatment system), and discharge water, and may be collected as part of the vessel’s annual survey as appropriate. Records of the sampling and testing results must be retained onboard for a period of 3 years in the vessel’s recordkeeping documentation consistent with Part 4.2.

Our services offer the following

Sampling Kits packed with all the necessary materials for sampling

Transportation of the kits towards the vessels

Step – by – Step Sampling Instructions

Transportation of the samples to the lab in the required time frames

Analysis as per EPA designated methods

Reporting as per EPA requirement

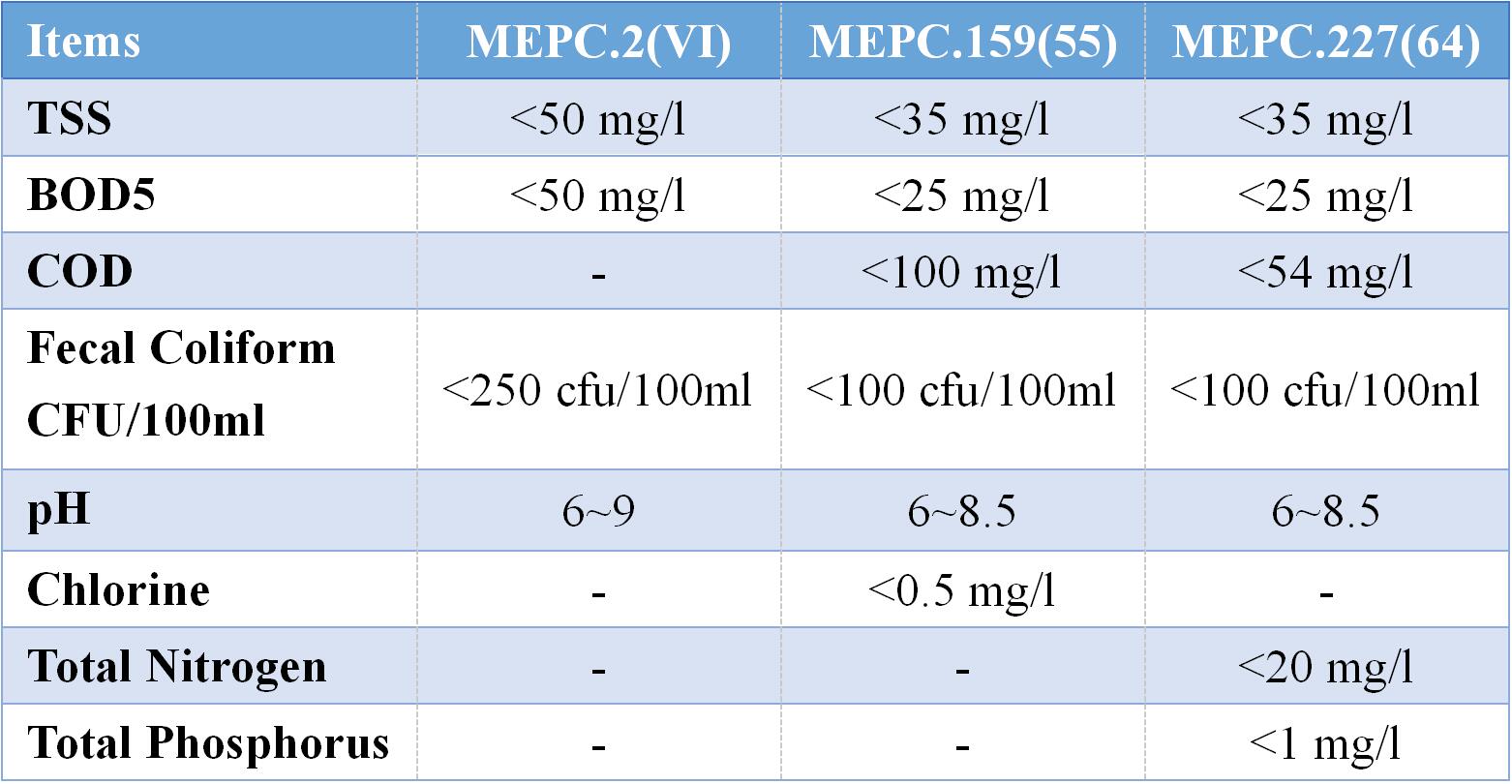

Sewage Effluent Testing

Marpol Annex IV contains a set of regulations regarding the discharge of sewage into the sea from ships, including regulations regarding the ships' equipment and systems for the control of sewage discharge, the provision of port reception facilities for sewage, and requirements for survey and certification.

Sewage treatment plants installed prior to 1 January 2010 on ships other than passenger ships operating in MARPOL Annex IV special areas and intending to discharge treated sewage effluent into the sea, should comply with resolution MEPC.2(VI).

Sewage treatment plants installed prior to 1 January 2016 and on or after 1 January 2010, on ships other than passenger ships operating in MARPOL Annex IV special areas and intending to discharge treated sewage effluent into the sea, should comply with resolution MEPC.159(55).

Sewage treatment plants installed on or after 1 January 2016 on ships, other than passenger ships, in all areas; and passenger ships outside MARPOL Annex IV special areas, should comply with resolution MEPC.227(64).

In line with Annex IV Prevention of Pollution by Sewage from Ships, sewage treatment plants should be kept in good condition, properly maintained, fully functional, with appropriate spares. A port authority can instruct a survey of the system at any time, and if the system is shown not to substantially comply – that is to perform to type approval – then the vessel can be held in port until repairs are completed (Regulation 4(5)).

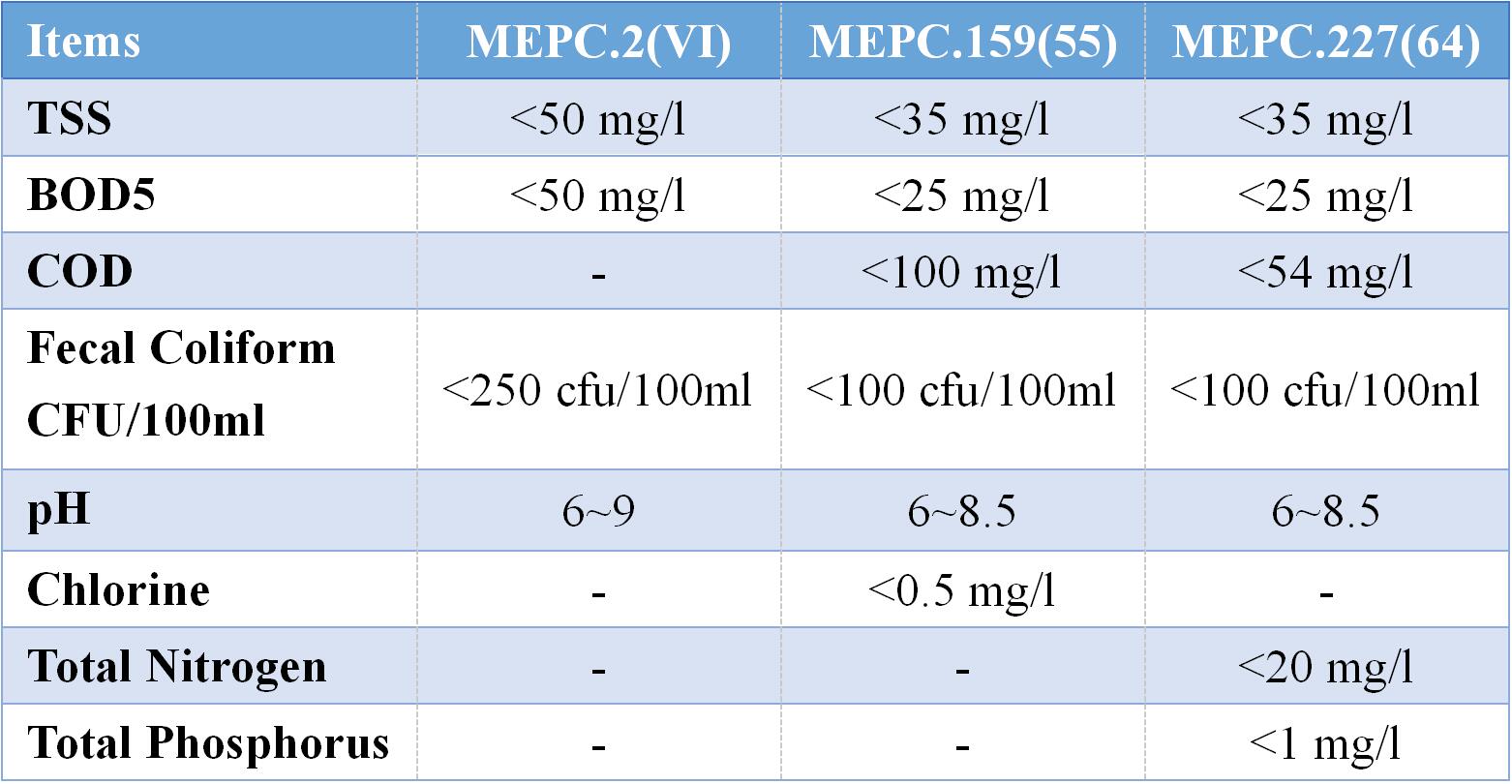

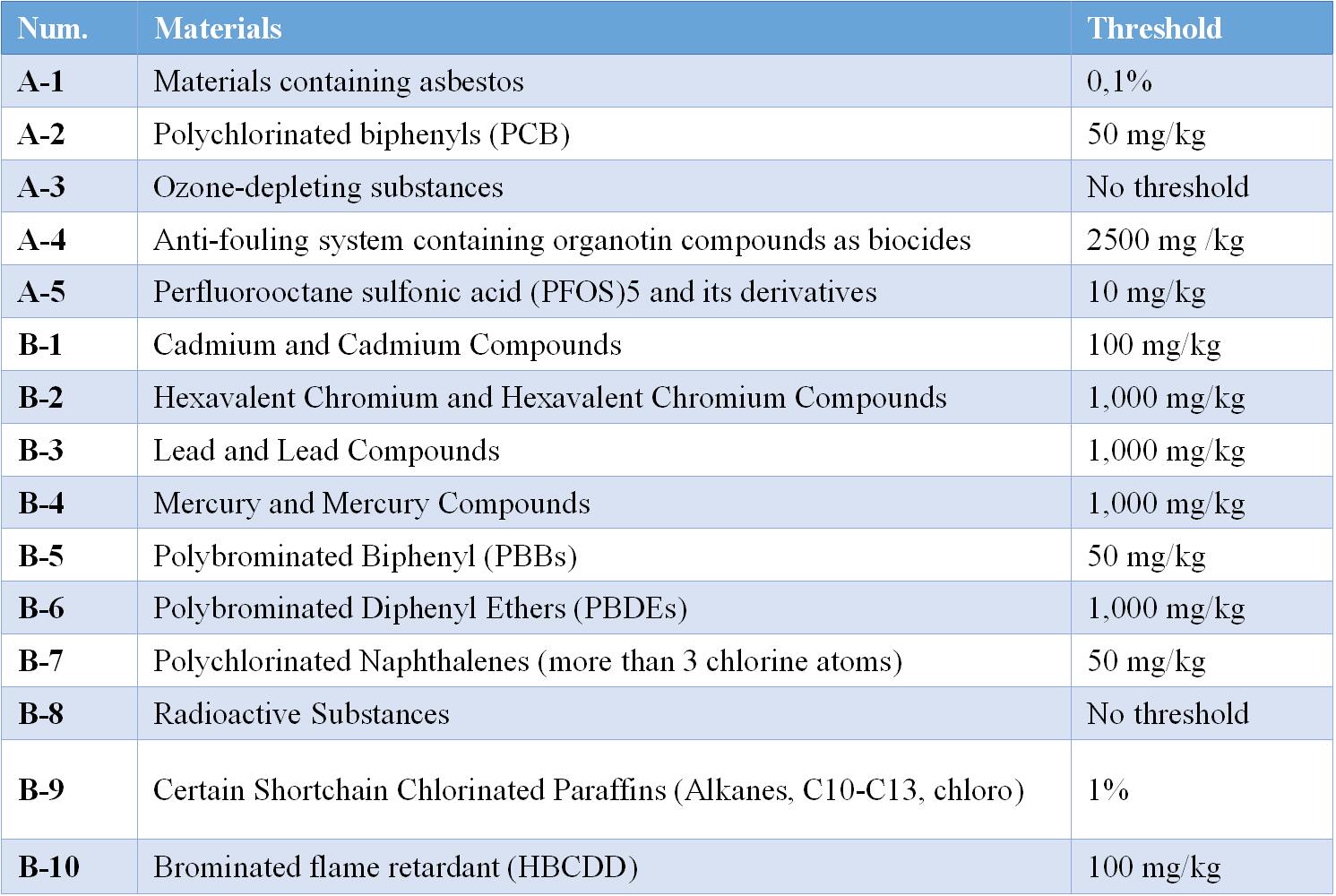

IHM Testing

IHM is a list that provides ship-specific information on the actual hazardous materials present on board, their location and approximate quantities. The IHM has following parts:

I : Materials contained in ship structure or equipment

II: Operationally generated wastes

III: Stores

There are two main legislations with respect to ship recycling in the market, one is IMO Hong Kong Convention (HKC) SR/CONF/45 and the other one is the EU Ship Recycling Regulation (EU SRR) EC No 1257/2013. HKC has in total 6 guidelines and MEPC.269(68) is the guidelines for the development of the inventory of hazardous materials (IHM) under IMO.

According to the EU SRR:

a) New ships flying a flag of an EU member state, shall be delivered with a valid IHM which is certified;

b) End-of-life ships going for recycling shall have a valid IHM certified and shall be sent to one of the recycling facilities in the EU List of approved ship recycling facilities.

c) Existing ships flying the flag of an EU member state and third-party ships visiting EU ports and anchorages, from 31 December 2020, shall have a valid IHM on-board, which is certified.

The following testing services are offered.